Film&Tape

MTI ECO INNOVATION

Film&Tape

Mold Release Film

Mold Release Film, Anti-Static Mold Release Film

Keeping the mold clean from materials such as silicone or epoxy, excellent release performance with no resin in the cavity Applicable in matte type for semiconductor packing or glossy type for LED manufacturing.

Description

- The film is vacuum adsorbed on the mold cavity surface so that the EMC resin does not come into direct contact with the cavity surface

- Environmentally superior by using film compared to the existing release material application molding method

- Mold tool maintenance is easy and can be applied to packages with complex phenomena

- Addition of anti-static function while maintaining the characteristics of the existing mold release film

- Composition of thin film conductive material between layers of film

- Prevention of static electricity generation by allowing microcurrent to flow well through conductive materials

Applications

- C-Mold, T-Mold

Properties

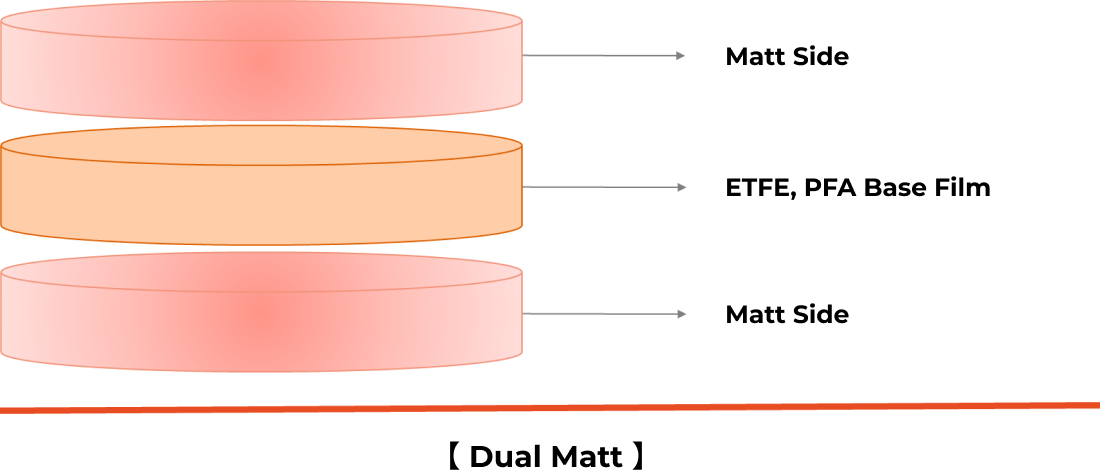

- Customized responses to various customer needs (film thickness, single/double-sided matte, matte surface, etc.)

- Applicable to semiconductor PKG or Glossy Film LED requiring surface roughness

- Prevention of mold tool contamination from materials such as silicon and epoxy

- Can be used at high temperatures over 200℃

- Excellent release property, no residue in the cavity

- Semi-permanent maintenance of anti-static function

- Maintenance of anti-static function even in high-temperature process

Product

Structure